Peerless Tips About What Is PWM Good For

Blog

Peeking Behind the Curtain

1. The Basics of PWM

So, you've stumbled upon the acronym PWM and are wondering, "What is PWM good for?" Well, let's demystify it. PWM, or Pulse Width Modulation, isn't some complicated alien technology. It's actually a pretty clever way of controlling the amount of power delivered to an electrical device. Think of it like this: instead of simply turning something fully on or fully off, PWM allows you to control the percentage of time it's on. Its like a dimmer switch, but instead of a knob, it uses rapid on-off cycles.

Imagine you're trying to fill a bucket with water. If you turn the tap on full blast, the bucket fills quickly. If you barely turn it on, it trickles in slowly. PWM is like turning the tap on and off really, really fast. The longer the tap is on during each cycle (the "pulse width"), the more water ends up in the bucket. This translates to more power delivered to the device. By adjusting the "width" of the pulse, we can fine-tune the amount of power.

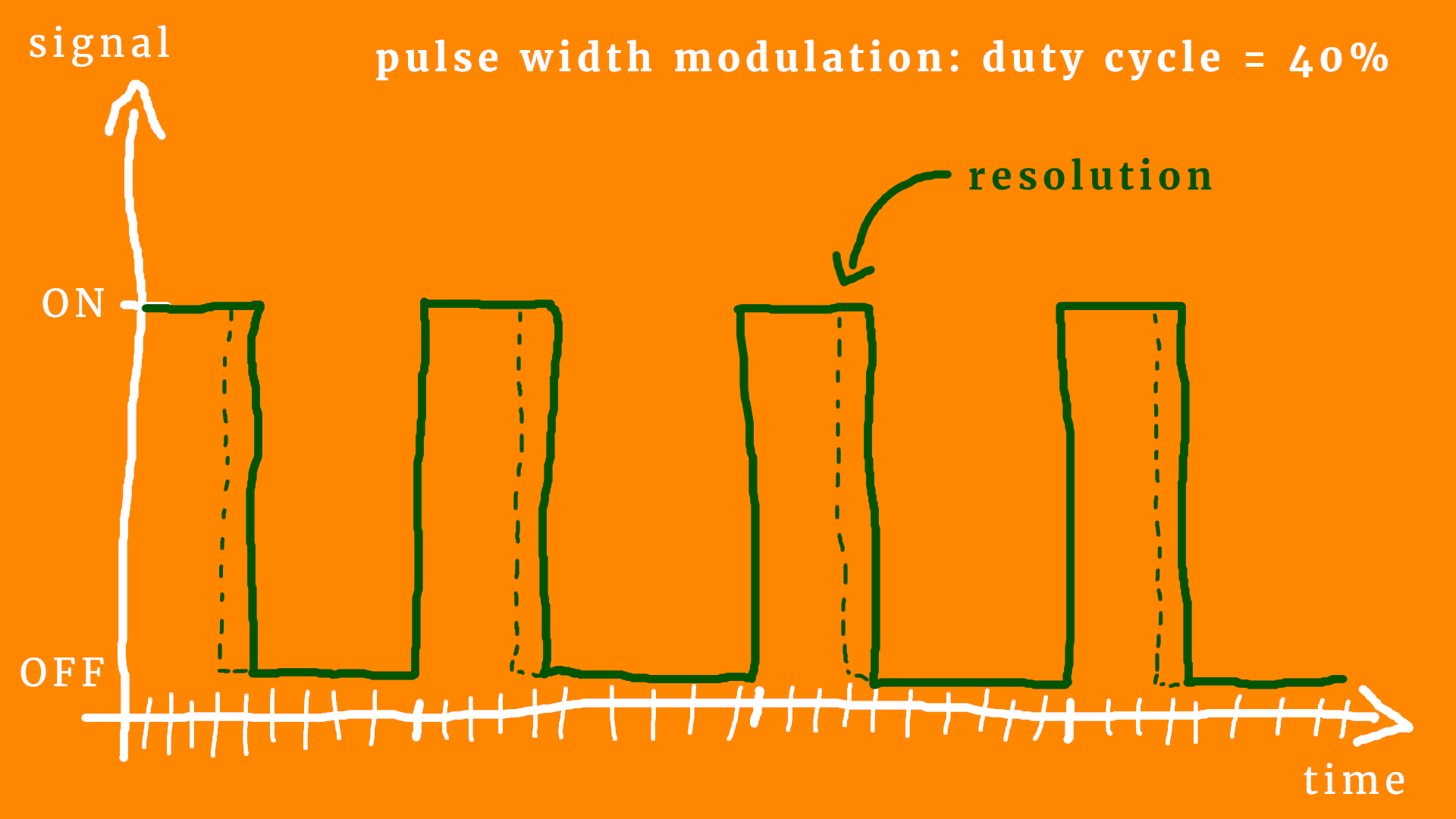

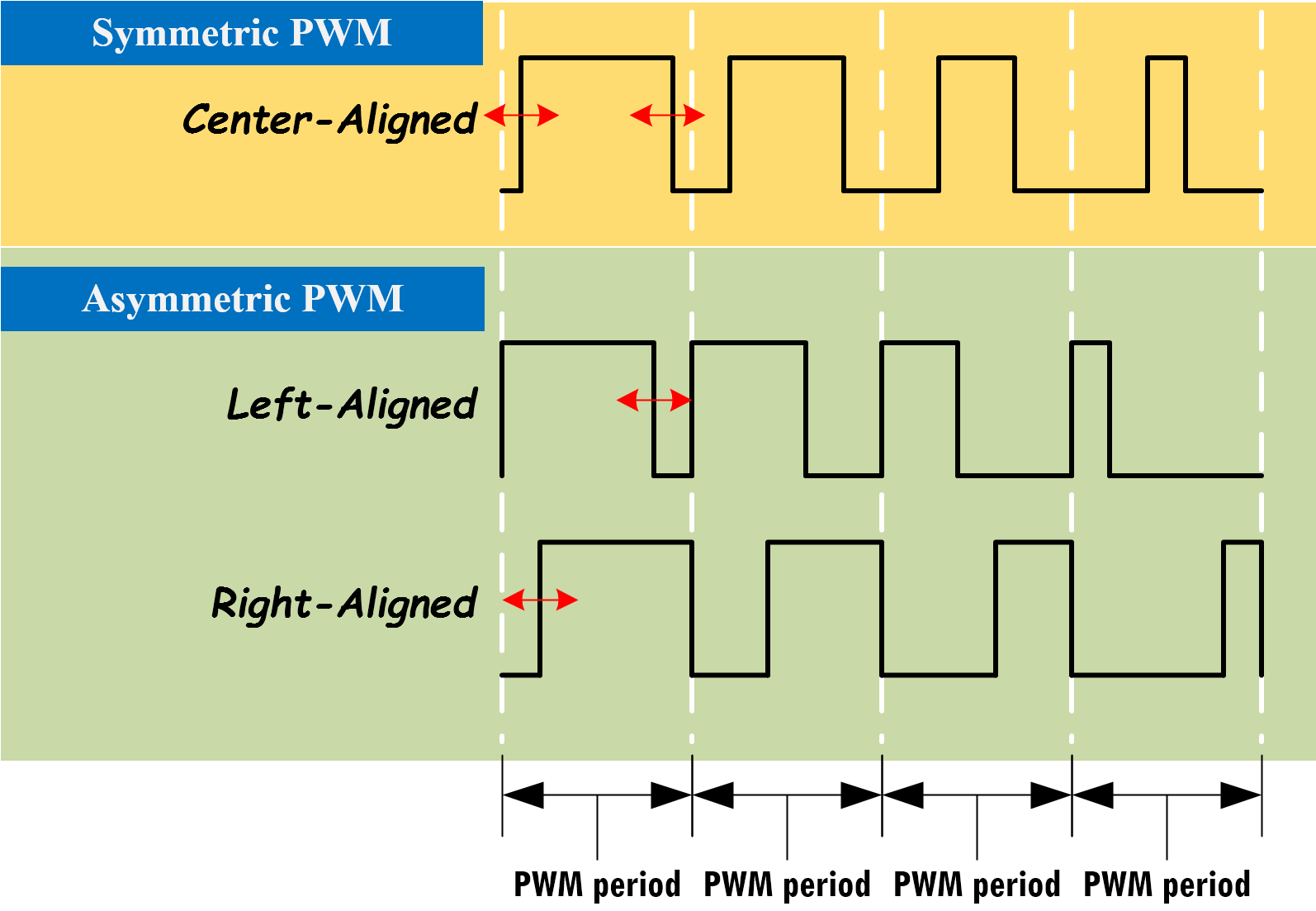

Technically speaking, PWM works by varying the duty cycle of a signal. The duty cycle is the percentage of one period in which a signal is active. A 50% duty cycle means the signal is on half the time and off half the time. A 90% duty cycle? On almost all the time! This rapid switching fools the device into acting as if it's receiving a lower average voltage, allowing for precise control.

It's not just about turning things down, though. PWM allows for very precise adjustments. This level of control is incredibly valuable in a whole host of applications, as you'll see.

2. The Wonderful World of Applications

Now that we know what PWM is, let's talk about where it's used. You might be surprised by how many everyday devices rely on PWM to function properly. Think about the brightness of your phone screen. How about the speed of your computer fan? Or even the power delivered to a small motor? Yup, all PWM at work!

One of the most common applications is controlling the speed of DC motors. In a toy car, for example, PWM is used to regulate the motor's speed, allowing it to move slowly or quickly. This is far more efficient and precise than simply reducing the voltage, which can lead to overheating and reduced torque (the motor's turning power). By modulating the pulse width, you can control both speed and torque effectively.

LED lighting is another area where PWM is a star. Dimming LEDs using PWM is far more efficient than using a resistor to reduce the current. By controlling the amount of time the LED is on, you can adjust its brightness without wasting energy. This is why many modern lighting systems use PWM for dimming control — it saves energy and extends the lifespan of the LEDs. Ever noticed that smooth fade-in/fade-out effect on some LED lights? That's PWM in action!

And let's not forget about audio amplifiers. PWM is used in Class-D amplifiers, which are highly efficient audio amplifiers. These amplifiers use PWM to switch the output transistors on and off rapidly, creating a signal that closely resembles the input audio signal. The efficiency gains are significant compared to traditional analog amplifiers, making them popular in portable devices and high-power audio systems.

3. Benefits of PWM

So, why is PWM so popular? What advantages does it offer over other control methods? Well, one of the biggest benefits is its efficiency. Because the switching devices (transistors, MOSFETs, etc.) are either fully on or fully off, they dissipate very little power. This makes PWM a highly efficient method for controlling power, which is especially important in battery-powered devices.

Another advantage of PWM is its precision. By adjusting the duty cycle, you can achieve very fine control over the amount of power delivered to the device. This is essential for applications where precise control is critical, such as robotics and motor control.

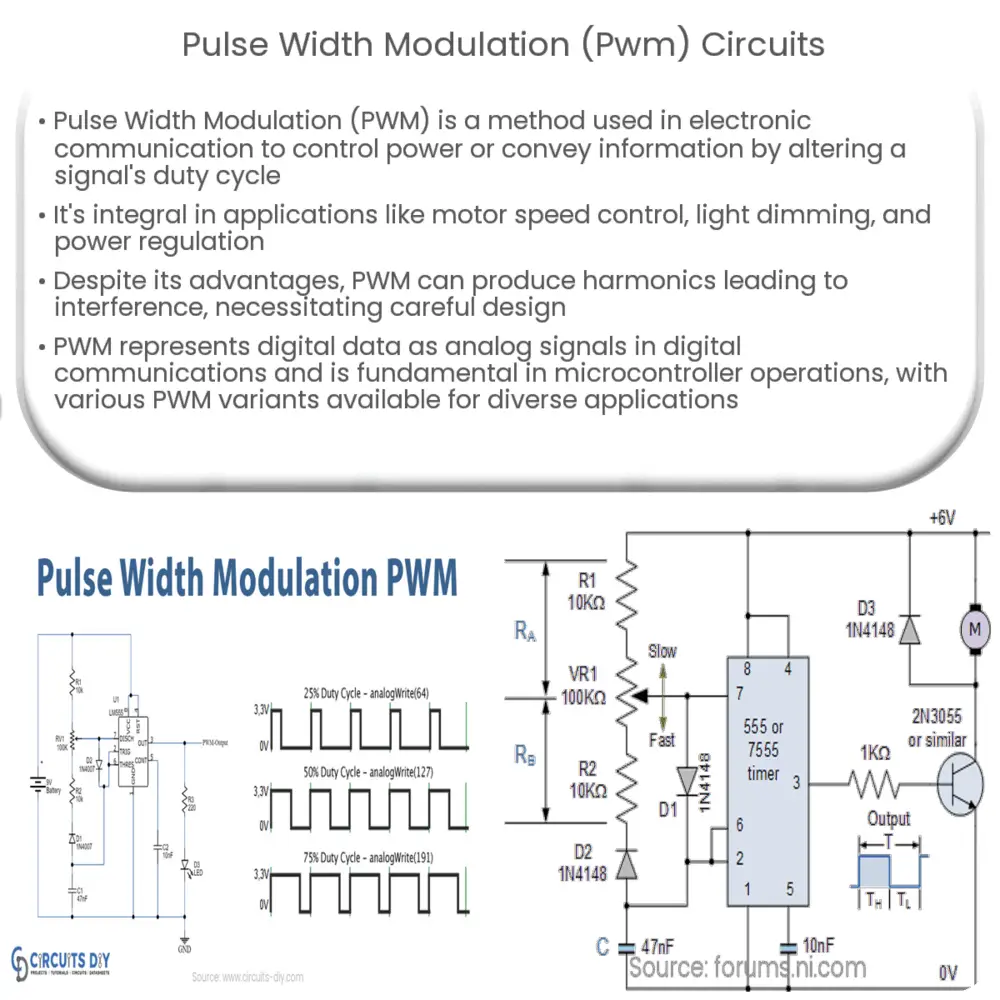

PWM is also relatively simple to implement. Microcontrollers often have built-in PWM modules, making it easy to generate PWM signals without requiring complex circuitry. This simplicity reduces cost and complexity, making PWM an attractive option for a wide range of applications.

Finally, PWM offers flexibility. It can be used to control a wide variety of devices, from motors and LEDs to heating elements and audio amplifiers. This versatility makes it a valuable tool for engineers and hobbyists alike. Plus, since the power devices are either fully on or fully off, heat generated can be more readily dissipated with a heat sink.

4. Potential Downsides

While PWM has many advantages, it's not without its drawbacks. One potential issue is electromagnetic interference (EMI). The rapid switching of PWM signals can generate noise that can interfere with other electronic devices. This is usually mitigated through proper shielding and filtering techniques.

Another potential issue is the switching frequency. If the switching frequency is too low, it can cause noticeable flicker in LEDs or audible noise in motors. Choosing an appropriate switching frequency is important to avoid these issues. Typically, higher switching frequencies are better, but they can also increase switching losses, slightly decreasing efficiency.

Also, in some very sensitive applications, the inherent on/off nature of PWM can introduce unwanted ripple in the output voltage or current. This can be addressed using filters, but they add complexity and cost to the circuit.

Despite these potential drawbacks, the advantages of PWM generally outweigh the disadvantages, making it a popular choice for a wide range of applications.

5. PWM in the Future

The use of PWM is only likely to increase in the future. As electronic devices become more sophisticated and energy efficiency becomes more important, PWM will continue to play a vital role in controlling power and optimizing performance.

With the rise of the Internet of Things (IoT), PWM will likely be used in a wider range of connected devices, from smart lighting systems to intelligent appliances. Its efficiency and flexibility make it well-suited for these applications. Imagine a future where your smart thermostat uses PWM to precisely control the heating and cooling system, optimizing energy consumption and maintaining a comfortable temperature.

Developments in semiconductor technology are also driving the adoption of PWM. New switching devices with faster switching speeds and lower losses are making PWM even more efficient and effective. This allows for higher switching frequencies, reducing EMI and improving performance.

Ultimately, PWM will likely remain a core technology for controlling power in electronic devices for many years to come. Its simplicity, efficiency, and flexibility make it an indispensable tool for engineers and designers. As our technology continues to evolve, PWM will continue to evolve along with it.

Frequently Asked Questions About PWM

6. Q

A: Linear voltage regulation works by dissipating excess power as heat to reduce the voltage. PWM, on the other hand, rapidly switches the power on and off, effectively controlling the average power delivered. PWM is far more efficient because it minimizes the amount of power dissipated as heat. Think of it like this: linear regulation is like driving with your foot on the brake, while PWM is like tapping the accelerator.

7. Q

A: While PWM is primarily used for controlling DC voltage, it can be used to control AC voltage through techniques like phase-angle control or by using it to generate a pseudo-sine wave that approximates AC. However, these methods are more complex and often require additional circuitry.

8. Q

A: The optimal switching frequency depends on the application. Higher frequencies generally reduce flicker and noise but can also increase switching losses. For LED dimming, a frequency above 200 Hz is usually sufficient to avoid noticeable flicker. For motor control, the frequency should be high enough to avoid audible noise but low enough to minimize switching losses. Experimentation and careful consideration of the application requirements are key!

Air Supply Lab Lesson 13 PulseWidth Modulation (PWM)