Real Tips About What Is A Wire Pull Box

The Difference Between Pull Box , Back And Junction YouTube

Demystifying the Wire Pull Box

1. What's the Deal with Wire Pull Boxes?

Ever peered into an electrical project and seen what looks like a metal or plastic box stuck in the middle of a bunch of wires? Chances are, you've spotted a wire pull box. These unassuming containers are actually pretty important pieces of electrical infrastructure. Think of them as pit stops for electrical wires, a place where they can take a breather and change direction.

Essentially, a wire pull box is an enclosure used in electrical wiring systems to facilitate the pulling of conductors (wires) through conduit. Conduit, by the way, is just a fancy word for the protective tubing that wires run through. Now, you might be wondering, why not just run the wires straight through? Well, long runs, multiple bends, or tight spaces can make pulling wires incredibly difficult, even impossible, without damaging them. That's where the pull box steps in to save the day.

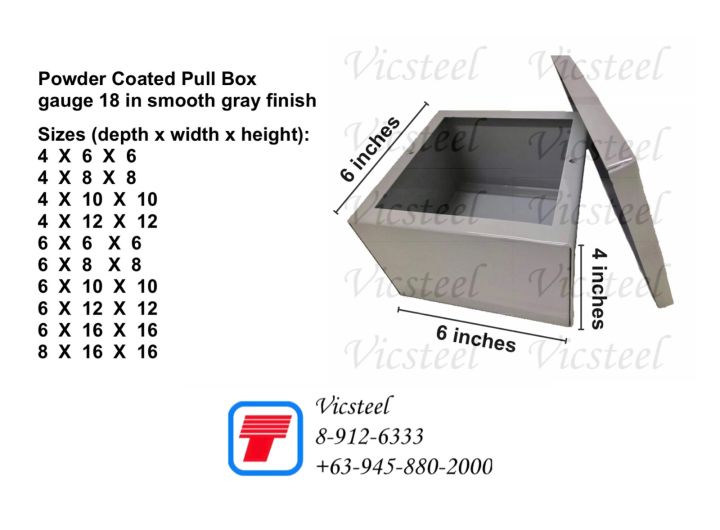

These boxes come in various shapes and sizes, from small squares to larger rectangles, and are constructed from materials like steel, aluminum, or plastic. The choice of material often depends on the environment where the box will be installed. For example, a damp location might call for a corrosion-resistant plastic box.

So, the next time you see one of these boxes, remember it's not just a random container; it's a carefully placed component that helps keep our electrical systems running smoothly and safely. And believe me, a smoothly running electrical system is something we can all appreciate.

Is It Possible To Cut Out Side Of Pull Box And Install A Grommet

Why Are Wire Pull Boxes Necessary? The Nitty-Gritty

2. Pulling Power

Okay, so we know what a wire pull box is, but let's dig a little deeper into why they're so vital. Imagine trying to thread a needle with a mile-long piece of thread that's also tangled. Sounds frustrating, right? That's kind of what pulling wires through long conduit runs without a pull box is like.

One major reason is friction. As wires are pulled through conduit, they rub against the inner walls. The longer the run and the more bends involved, the more friction there is. Excessive friction can damage the wire's insulation, potentially leading to short circuits, electrical fires, and other not-so-fun outcomes. Pull boxes provide access points to reduce the pulling distance, thus minimizing friction and protecting the wires. It's like breaking up a long road trip with rest stops.

Another important aspect is bend radius. Electrical codes specify minimum bend radii for wires to prevent damage to the insulation and conductors. Without a pull box, it might be impossible to achieve the required bend radius when changing direction within a tight space. The box allows for a gentler, code-compliant bend.

Beyond reducing friction and facilitating bends, pull boxes also make future maintenance and upgrades easier. Need to add a circuit or replace a wire? A pull box provides convenient access to the wiring, eliminating the need to rip out entire sections of conduit. Think of it as a strategic access panel for your electrical system.

Types Of Electrical Pull Boxes At Katie Felton Blog

Types of Wire Pull Boxes

3. Choosing the Right Box for the Job

Not all wire pull boxes are created equal. They come in various types, each designed for specific applications. The most common types include junction boxes, pull boxes, and splice boxes. While the terms are sometimes used interchangeably, there are subtle differences.

Junction boxes are primarily used to join or branch electrical circuits. They typically house wire connections and provide a safe enclosure for these connections. Think of them as the central hubs of your electrical wiring system.

Pull boxes, as we've discussed, are mainly for facilitating wire pulling through conduit runs. They might contain splices, but their primary purpose is to reduce friction and make wire installation easier. They're like strategically placed assist stations along a racecourse.

Splice boxes, on the other hand, are specifically designed to house wire splices. These boxes often have more internal space than junction boxes to accommodate the bulk of the splices. Imagine them as specialized storage containers just for wire connections.

Besides these functional classifications, pull boxes are also categorized by material (metal or non-metal) and enclosure type (NEMA ratings). The choice depends on the environmental conditions and the specific requirements of the electrical installation. It's all about selecting the right tool for the job to ensure safety and longevity.

What Is A Pull Box In Electrical At James Glassop Blog

Installation Considerations

4. Safe and Sound

Installing a wire pull box might seem straightforward, but it's crucial to follow proper procedures to ensure safety and code compliance. Improper installation can lead to electrical hazards and costly rework. So, let's cover some key considerations.

First and foremost, always disconnect the power before working on any electrical wiring. This might seem obvious, but it's a step that's often overlooked, with potentially disastrous consequences. Think of it as putting on your seatbelt before driving — a simple precaution that can save your life.

Next, select the appropriate size and type of pull box for the application. The National Electrical Code (NEC) provides guidelines for sizing pull boxes based on the number and size of conductors entering and exiting the box, as well as the conduit size. Don't try to cram too many wires into a box that's too small; it can lead to overheating and insulation damage.

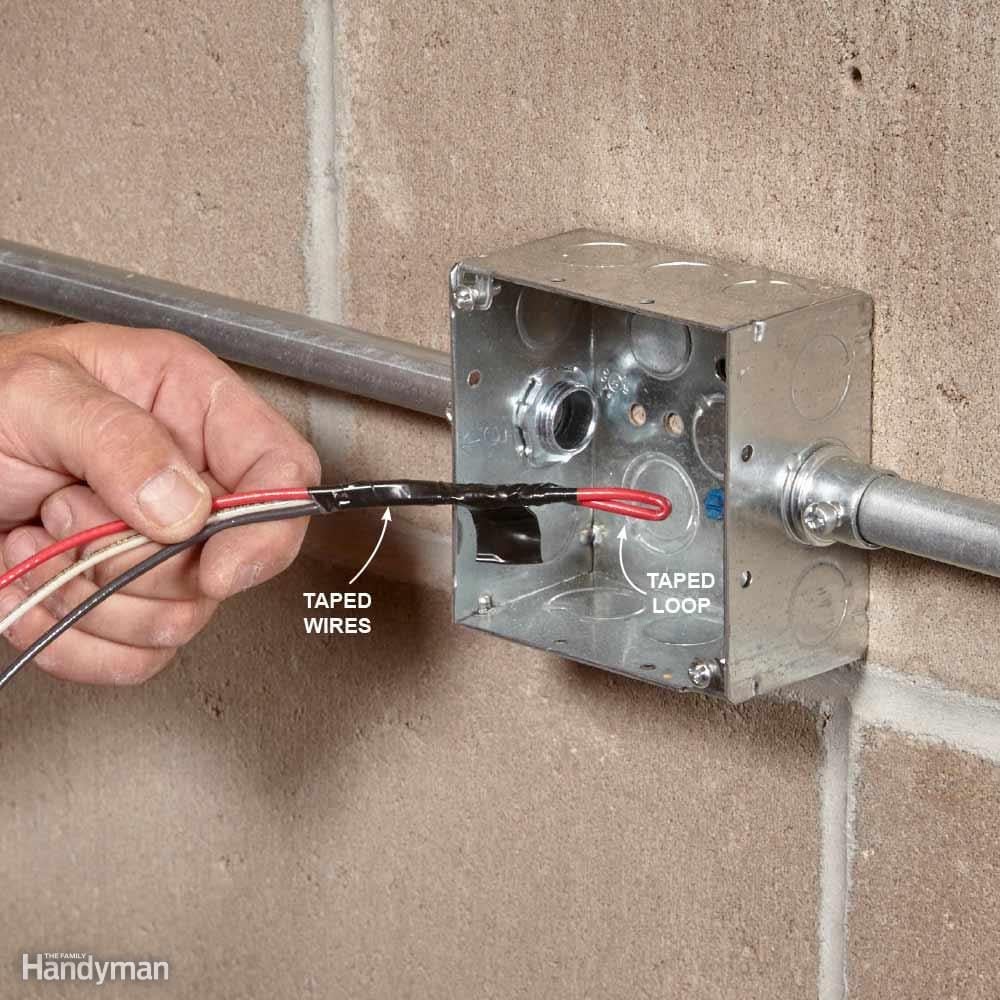

When installing the box, ensure it's securely mounted and properly grounded. Grounding provides a path for fault current to flow back to the source, tripping the circuit breaker and preventing electrical shock. It's like having a safety valve on a pressure cooker.

Finally, be meticulous about wire management within the box. Neatly arrange the wires, ensuring that connections are secure and insulated. Avoid sharp bends or kinks in the wires, as these can damage the insulation over time. A well-organized pull box not only looks professional but also makes future troubleshooting and maintenance much easier.

Frequently Asked Questions (FAQs) About Wire Pull Boxes

5. Your Burning Questions Answered!

Still scratching your head about wire pull boxes? Here are some common questions and answers to clear things up:

Q: Do I really need a wire pull box? Can't I just muscle the wires through?A: While you might be able to force wires through without a pull box in some cases, it's generally not a good idea. You risk damaging the wires, violating code, and making future maintenance a nightmare. Think of it as trying to fit a square peg in a round hole — it might work with enough force, but you'll likely break something in the process.

Q: What's the difference between a metal and a plastic wire pull box?A: Metal boxes are typically stronger and more durable, making them suitable for industrial or outdoor environments. They also provide better electromagnetic shielding. Plastic boxes, on the other hand, are lighter, corrosion-resistant, and often less expensive. The choice depends on the specific application and environmental conditions.

Q: Can I paint a wire pull box?A: Yes, you can paint a wire pull box, but it's important to use a paint that's compatible with the box material. Avoid using metallic paints on plastic boxes, as this can create a potential shock hazard. Also, be sure to mask off any labels or markings on the box before painting.

Q: How do I know what size wire pull box to use?A: The NEC provides specific guidelines for sizing wire pull boxes based on the number and size of conductors entering and exiting the box. Consult the NEC or a qualified electrician for assistance in determining the appropriate size for your application.